The manufacture of light boxes is the most important specialty of M&M Graphic. They are among its most popular products.

As M&M manufactures this case from A to Z and it is custom-made for each customer at its Montreal workshops, we are assured of the guarantee of a top-of-the-range quality product, and this at the highest cost. reasonable. Especially since as everything is done locally, the deadlines are really very advantageous!

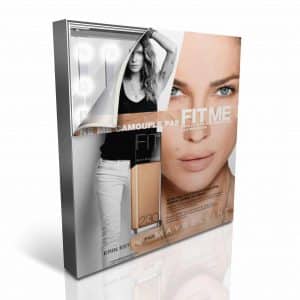

There are different models of light boxes, which can be grouped into two main categories: backlit light boxes (backlite) and those that are lit on the edge (edgelite). Even within each of the categories, there are different thickness options for the light box frame.

In the choices available for the backlite, there are mainly two options: the 55 millimeters (T-55) and the 100 millimeters (the T-100). It is advisable to order T-55 when the size of the box is smaller, i.e. below 6 feet by 6 feet approximately.

The T-100 is thicker so better suited to larger sizes, such as 8ft by 8ft or larger. The T-100 is also more economical per square foot than the T-55. The reason ? Its LED modules are larger and less expensive than the strip modules of the T-55.

In the choices available for the edgelite, it is essentially the 120 millimeter thick model (T-120) that is offered. It is this model that we find in large format in shopping centers, chain stores, as well as for large windows.

Note that there are many more choices of thicknesses of extrusions that can be used for the production of light boxes. Only the main ones are identified here because these are the models sold in more than 90% of cases. These are the most popular, often the best suited to the display context in stores or museums.

Note that there are no templates on the website for light boxes (same for wall frames without lighting). It’s just that all light boxes and wall frames are custom made, according to the dimensions provided by customers. There is therefore no standard in this product niche.

How to prepare the files then? Simply format the image or montage to the final light box or frame size and add a half inch all the way around the image, in “bleed” or “bleed”. This applies to a canvas that will have a medium or small format, that is to say 4 feet by 4 feet approximately. For larger formats (example 8 feet by 8 feet or more), it is advisable to reserve an inch of bleed margins all around the image to allow for finishing adjustment.

This margin is important because it compensates for the shrinkage of the canvas due to the heat of the press, and the reaction of the fabric to sublimation and inks. It is also in this excess image that we will reserve a space for the sewing value. This is a value of a quarter inch for canvases with silicone rods and half an inch for hems.

Contact an advisor to learn more about finishing issues.